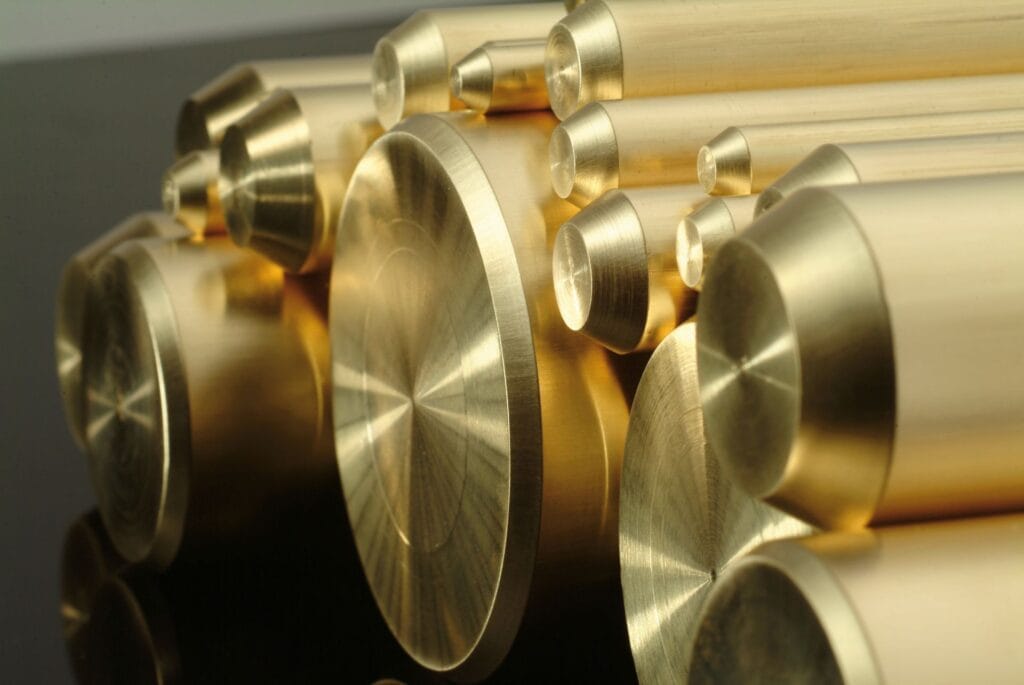

Material: Cu~67%, Zn~33%

Brass

Brass is an alloy composed primarily of copper and zinc. Its color varies from reddish-yellow to light yellow depending on the zinc content, with higher zinc content resulting in a lighter color. While density varies with composition, it is typically around 8.4-8.7 g/cm³. The melting point is generally lower than pure copper, typically ranging from 900-1000°C. Brass is known for its good machinability, corrosion resistance, and acoustic properties. It is widely used in the manufacture of valves, pipes, fittings, musical instruments, decorative items, and ammunition casings.

Brass Products

| Name | Definition | Features | Size Range | Common ASTM Grades | Main Applications |

|---|---|---|---|---|---|

| Brass Pipe/Tube | Hollow round or shaped brass tube, Pipe is large diameter pipe, Tube is small diameter tube | Corrosion resistant, easy to weld; higher strength than pure copper, suitable for fluid transport | Wall Thickness: 0.5-10mm Outer Diameter: 3-200mm | C44300, C46400, C23000, C28000, C26000, C27000 | Water pipes, musical instrument tubes (e.g., horns), heat exchanger tubes |

| Brass Bar/Rod | Solid long brass material, Rod is round, Bar is square/rectangular/hexagonal | High strength, easy to turn, forge; suitable for mechanical processing | Diameter/Side Length: 3-100mm Length: 1-6m | C36000, C37700, C27200, C38500, C34200, C46400, C26000, C28000 | Bolts, valves, gears, mechanical parts |

| Brass Foil/Strip | Continuous rolled brass (Foil) or cut narrow strips (Strip, width < 600mm) | Good flexibility, suitable for continuous stamping and precision processing; high surface quality | Thickness: 0.1-3mm Width: 10-600mm | C26000, C27200, C27000, C26800, C21000, C22000 | Electronic connectors, springs, heat sinks, decorative strips |

| Brass Plate/Sheet | Flat brass plates (Plate, thickness > 6mm) or sheets (Sheet, thickness 0.15-6mm) | Glossy surface, easy to stamp, bend; higher strength and corrosion resistance than pure copper | Thickness: 0.15-100mm Width: 100-2000mm | C26000, C27200, C27000, C26800, C23000, C22000, C28000, C44300, C46400 | Decorative panels, nameplates, heat exchanger plates, architectural trim |

Brass Standards Comparison

| USA (ASTM) | China (GB) | Europe (EN) | International (ISO) | Main Composition | Characteristics |

|---|---|---|---|---|---|

| C21000 | H96 | CuZn5 | CuZn5 | Cu~95%, Zn~5% | 95/5 Brass (Gilding Metal), golden color, excellent ductility, easy deep drawing |

| C22000 | H90 | CuZn10 | CuZn10 | Cu~90%, Zn~10% | 90/10 Brass (Commercial Bronze), light yellow color, good ductility, corrosion resistant |

| C23000 | H85 | CuZn15 | CuZn15 | Cu~85%, Zn~15% | 85/15 Brass (Red Brass), reddish color, good ductility, excellent cold working performance |

| C24000 | H80 | CuZn20 | CuZn20 | Cu~80%, Zn~20% | 80/20 Brass (Low Brass), yellower color, good cold working performance |

| C26000 | H70 | CuZn30 | CuZn30 | Cu~70%, Zn~30% | 70/30 Brass (Cartridge Brass), excellent deep drawing performance, superior cold working performance |

| C26800 | H68 (CuZn32) | CuZn33 | CuZn33 | Cu~67%, Zn~33% | 67/33 Brass (Yellow Brass), balanced strength and ductility, good cold working performance |

| C27000 | H65 (CuZn35) | CuZn35 | CuZn35 | Cu~65%, Zn~35% | 65/35 Brass (Yellow Brass), good overall performance, general purpose brass |

| C27200 | H63 | CuZn37 | CuZn37 | Cu~63%, Zn~37% | 63/37 Brass (Yellow Brass), one of the most common brasses, good hot and cold working properties |

| C28000 | - | CuZn40 | CuZn40 | Cu~60%, Zn~40% | 60/40 Brass (Muntz Metal), higher strength, excellent hot working performance, but poor cold working performance |

| C34000 | - | CuZn35Pb1 | CuZn35Pb1 | Cu~65%, Zn~34%, Pb~1% | Leaded brass, good machinability |

| C34200 | - | CuZn35Pb2 | CuZn34Pb2 | Cu~64%, Zn~34%, Pb~2% | Leaded brass, excellent machinability, moderate strength and ductility |

| C35000 | HPb60-2 | CuZn38Pb2 | CuZn37Pb2 | Cu~61%, Zn~37%, Pb~2% | Leaded brass, excellent machinability, good hot forgeability |

| C36000 | HPb63-3 | CuZn36Pb3 | CuZn36Pb3 | Cu~61.5%, Zn~35.5%, Pb~3% | Free Cutting Brass, best machinability, suitable for automatic processing |

| C37700 | HPb60-2 | CuZn39Pb2 | CuZn38Pb2 | Cu~58%, Zn~39%, Pb~2% | Forging Brass, excellent hot forgeability, good machinability |

| C38000 | HPb59-1 | CuZn40Pb2 | CuZn40Pb2 | Cu~60%, Zn~38%, Pb~2% | Leaded brass, good hot workability, good machinability |

| C38500 | HPb58-2.5 | CuZn39Pb3 | CuZn39Pb3 | Cu~57%, Zn~40%, Pb~3% | Architectural Bronze, excellent hot workability, good machinability |

| C44300 | HSn70-1 | CuZn28Sn1As | CuZn28Sn1 | Cu~70%, Zn~29%, Sn~1%, As~0.06% | Admiralty Brass, tin added to improve seawater corrosion resistance, arsenic inhibits dezincification |

| C46400 | HSn60-1 | CuZn39Sn1 | CuZn39Sn1 | Cu~60%, Zn~39%, Sn~1% | Naval Brass, good strength and corrosion resistance, especially to seawater, can be hot worked |

FAQ

A1: According to production standards, we can also accept third-party inspections, and all products undergo strict quality inspection before packaging.

A2: It mainly depends on your location and demand, usually the delivery time is around 7-10 days after deposit arrived , if there is stock in our warehouse, we can send out within 3 days.

A3: We support custom products in different sizes, designs and finishes.

A4: Yes, we can provide samples for free, but need buyer to provide shipping cost. Also can provide customized samples according to your drawing , sample charge can be refunded when bulk order released