Material: Cu Rem., Sn 3.5-4.5%, P 0.03-0.35%

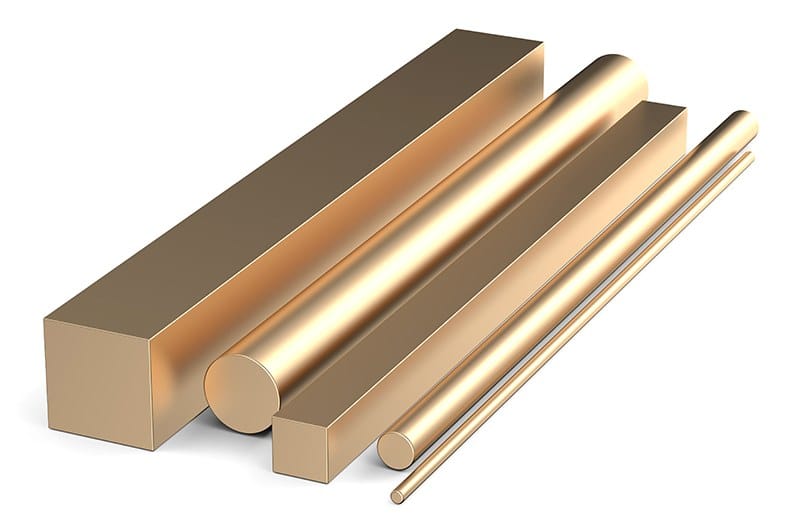

Bronze

Bronze is an alloy primarily composed of copper and tin. However, it can also contain other elements like phosphorus, manganese, aluminum, or silicon. It typically has a dull-gold color, though this can vary depending on the specific composition. Density varies with composition, often ranging from 7.4-8.9 g/cm³. The melting point is generally lower than brass, typically ranging from 850-1000°C. Bronze is known for its hardness, strength, ductility, wear resistance, and corrosion resistance, particularly in marine environments. Common applications include bearings, bushings, sculptures, bells, marine hardware, and certain types of tools.

Bronze Products (C50000-C59999)

| Name | Definition | Features | Size Range | Common ASTM Grades | Main Applications |

|---|---|---|---|---|---|

| Bronze Pipe/Tube | Hollow round or shaped bronze tube, Pipe is large diameter pipe, Tube is small diameter tube | Corrosion resistant, wear resistant, high strength; suitable for high-pressure fluid transport | Wall Thickness: 0.5-10mm Outer Diameter: 3-200mm | C51900, C52100, C52400 | Marine pipes, hydraulic pipes, pump pipes, heat exchanger tubes |

| Bronze Bar/Rod | Solid long bronze material, Rod is round, Bar is square/rectangular/hexagonal | High strength, wear resistant, easy to machine; suitable for heavy-duty parts | Diameter/Side Length: 3-100mm Length: 1-6m | C54400, C52100, C52400, C51900 | Bearings, gears, shafts, valve parts, marine fittings |

| Bronze Foil/Strip | Continuous rolled bronze (Foil) or cut narrow strips (Strip, width < 600mm) | High elasticity, fatigue resistant, suitable for precision stamping and spring manufacturing | Thickness: 0.1-3mm Width: 10-600mm | C51000, C51900, C51100, C52100, C52400 | Springs, electrical connectors, diaphragms, musical instrument parts |

| Bronze Plate/Sheet | Flat bronze plates (Plate, thickness > 6mm) or sheets (Sheet, thickness 0.15-6mm) | High strength, wear resistant, corrosion resistant; suitable for stamping and wear applications | Thickness: 0.15-100mm Width: 100-2000mm | C51000, C51100, C51900, C52100, C52400 | Wear plates, marine panels, molds, decorative parts |

Bronze Standards Comparison

| USA (ASTM) | China (GB) | Europe (EN) | International (ISO) | Main Composition | Characteristics |

|---|---|---|---|---|---|

| C51000 | - | CuSn5 | CuSn5 | Cu Rem., Sn 4.2-5.8%, P 0.03-0.35% | 5% Tin Bronze, high strength and elasticity, fatigue resistant, corrosion resistant |

| C51100 | QSn4-0.3 | CuSn4 | CuSn4 | Cu Rem., Sn 3.5-4.5%, P 0.03-0.35% | 4% Tin Bronze, lower strength and elasticity than C51000 but better ductility, corrosion resistant |

| C51900 | QSn6.5-0.1 | CuSn6 | CuSn6 | Cu Rem., Sn 5.5-7.0%, P 0.03-0.35% | 6% Tin Bronze, higher strength and elasticity than C51000, fatigue resistant, corrosion resistant |

| C52100 | QSn8-0.3 | CuSn8 | CuSn8 | Cu Rem., Sn 7.0-9.0%, P 0.03-0.35% | 8% Tin Bronze, high strength, elasticity, wear resistance, and fatigue resistance, stress relaxation resistant |

| C52400 | QSn10-1 | CuSn10 | CuSn10 | Cu Rem., Sn 9.0-11.0%, P 0.03-0.35% | 10% Tin Bronze, extremely high strength, elasticity, wear resistance, and fatigue resistance |

| C54400 | QSn4-4-2.5 (Approx.) | CuSn4Pb4Zn3 | CuSn4Pb4Zn3 | Cu 87.0-90.0%, Sn 3.5-4.5%, Pb 3.5-4.5%, Zn 1.5-2.5% | Free Cutting Tin Bronze, excellent machinability, good strength and wear resistance |

FAQ

A1: According to production standards, we can also accept third-party inspections, and all products undergo strict quality inspection before packaging.

A2: It mainly depends on your location and demand, usually the delivery time is around 7-10 days after deposit arrived , if there is stock in our warehouse, we can send out within 3 days.

A3: We support custom steel in different sizes, designs and finishes.

A4: Yes, we can provide samples for free, but need buyer to provide shipping cost. Also can provide customized samples according to your drawing , sample charge can be refunded when bulk order released